In today's competitive landscape, businesses seeking to enhance their product offerings often turn to EVA foam due to its versatile properties and applications across various industries, including automotive, packaging, and sports equipment. According to a report by Grand View Research, the global EVA foam market size was valued at approximately $8.03 billion in 2020 and is projected to expand at a CAGR of 5.2% from 2021 to 2028. Partnering with EVA foam manufacturers is not just a strategic move but also a smart investment that can lead to significant cost savings and improved product performance. These manufacturers possess specialized knowledge and advanced technology, enabling them to provide customized solutions that meet specific industry needs. By leveraging the expertise of EVA foam manufacturers, businesses can overcome common challenges related to material sourcing, optimization, and sustainability, ultimately gaining a competitive edge in their respective markets.

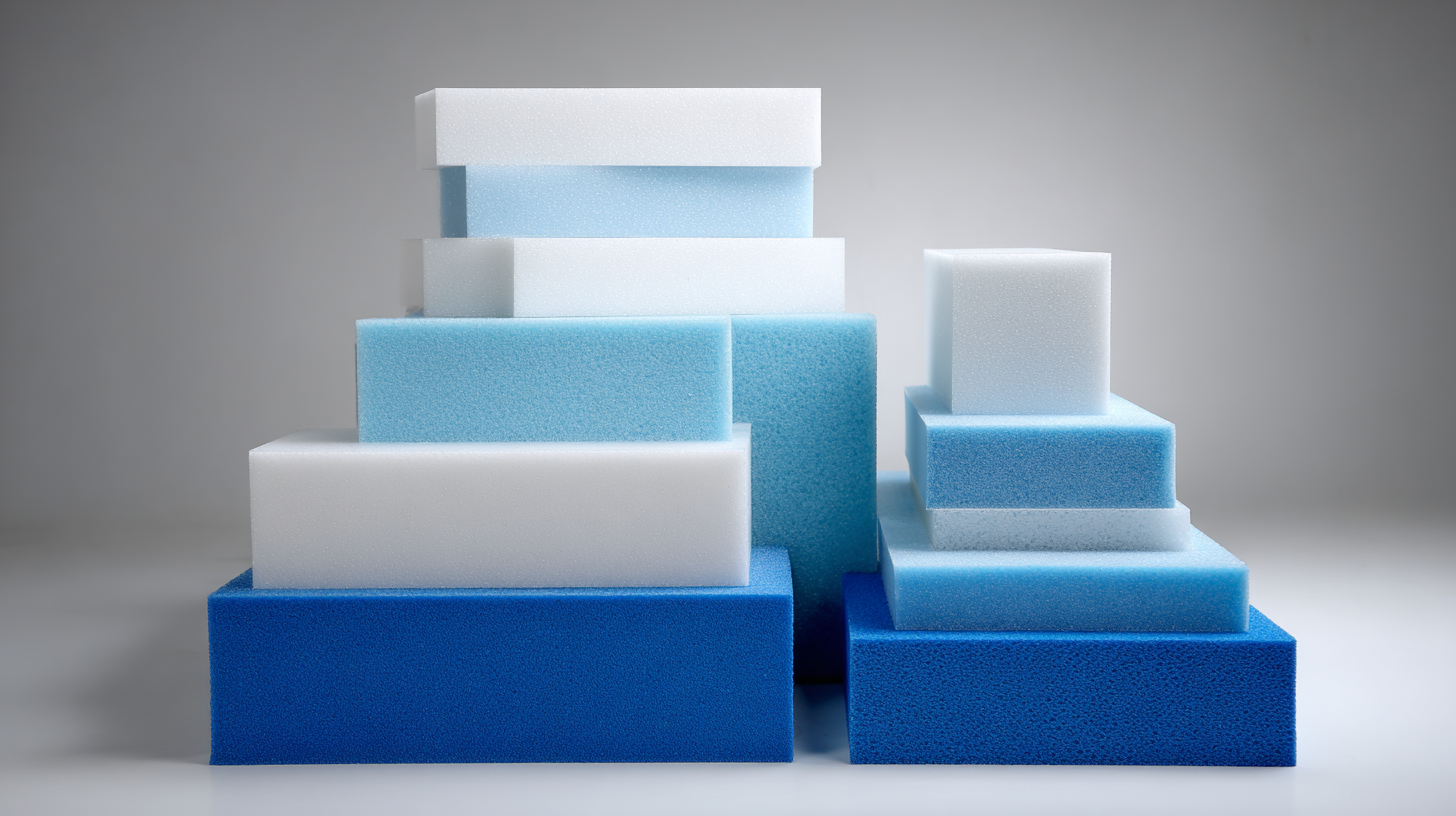

EVA foam has rapidly gained recognition for its versatility across various applications, making it an essential material in many industries. From outdoor gear to innovative home storage solutions, EVA foam effectively meets the diverse needs of modern consumers. For instance, it plays a pivotal role in products such as multifunctional trekking poles that cater to various outdoor activities while seamlessly integrating features like smartphone holders. This adaptability illustrates how EVA foam can enhance convenience and functionality in everyday items.

EVA foam has rapidly gained recognition for its versatility across various applications, making it an essential material in many industries. From outdoor gear to innovative home storage solutions, EVA foam effectively meets the diverse needs of modern consumers. For instance, it plays a pivotal role in products such as multifunctional trekking poles that cater to various outdoor activities while seamlessly integrating features like smartphone holders. This adaptability illustrates how EVA foam can enhance convenience and functionality in everyday items.

Moreover, companies are continuously exploring the potential of EVA foam beyond traditional uses. Innovations, such as combining EVA with materials like wood for aesthetic and functional home products, demonstrate the material's endless possibilities. The ability to mold and adapt EVA foam not only enhances product design but also opens avenues for manufacturers to create bespoke solutions that resonate with current trends. As businesses prioritize both quality and versatility, EVA foam stands out as a go-to choice for enhancing product performance and user experience.

Cost-effectiveness is a crucial consideration for businesses looking to optimize their manufacturing processes and improve profitability. Partnering with EVA foam manufacturers can lead to significant cost savings due to the material's inherent properties. According to a report by Smithers Pira, the global EVA foam market was valued at approximately $6.5 billion in 2020, projected to reach $11 billion by 2025, indicating strong demand and potential economies of scale for manufacturers. This growth suggests that partnerships with established EVA foam suppliers can reduce costs due to bulk purchasing agreements and lower material prices as production ramps up.

Furthermore, EVA foam's versatility and light weight can reduce shipping costs and material waste during production. A study published by TechSci Research highlights that using EVA foam in applications ranging from footwear to automotive components decreases overall manufacturing time and labor costs, which contributes to lower operational expenses. By strategically partnering with EVA foam manufacturers, businesses can leverage their expertise in optimizing the production process while ensuring high-quality output. This not only enhances the bottom line but also creates opportunities for innovation and competitiveness in the market.

Partnering with EVA foam manufacturers can significantly elevate the quality of your products. By collaborating with experts in the field, you gain access to innovative techniques and materials that enhance performance and durability. EVA foam manufacturers have extensive experience in developing solutions tailored to specific needs, which can lead to lighter, more flexible, and energy-absorbing products. This collaboration not only leverages their technical know-how but also allows for direct feedback during the development process, ensuring that the end product aligns with your vision.

When working with EVA foam experts, keep these tips in mind: first, maintain open communication about your product requirements and design intentions. This transparency will foster a more efficient collaboration. Secondly, don't hesitate to request prototypes early in the development phase; testing these samples can identify potential improvements before full-scale production. Lastly, explore the possibility of co-developing materials that not only meet your specifications but also innovate within your market segment—this can give you a competitive edge.

Embracing these strategies will maximize the advantages of partnering with EVA foam manufacturers, resulting in superior product quality and customer satisfaction.

In today’s environmentally conscious market, sustainability practices in EVA foam manufacturing are not just a trend but a necessity. By adopting eco-friendly methods, EVA foam manufacturers can minimize waste and resource consumption, thereby enhancing their competitive edge. For example, utilizing recycled materials in the production process reduces reliance on virgin resources and significantly lowers carbon footprints. This shift not only appeals to eco-aware consumers but also positions manufacturers as leaders in sustainable practices.

Tips for enhancing sustainability in EVA foam production include investing in energy-efficient machinery and optimizing production processes to reduce energy consumption. Manufacturers can also explore partnerships with organizations dedicated to environmental conservation, ensuring that their practices align with global sustainability standards. Additionally, embracing a circular economy approach by encouraging product take-back schemes can further reduce waste while promoting a positive brand image.

Engaging with suppliers who prioritize sustainable raw materials is another effective strategy. This collaboration ensures that all aspects of the production chain are environmentally responsible, from sourcing to processing. By these means, EVA foam manufacturers can create products that are not only innovative but also aligned with the growing demand for sustainable solutions in the marketplace.

The use of EVA foam in custom product development showcases its versatility and adaptability across various industries. According to Smithers Pira, the global EVA foam market is projected to reach $2.5 billion by 2025, driven by increasing demand in sectors such as sports, automotive, and consumer goods. This material not only provides excellent cushioning and shock absorption but also boasts waterproof and lightweight properties, making it ideal for innovative applications ranging from footwear to electronic packaging.

Partnering with specialized EVA foam manufacturers allows businesses to leverage these properties for tailored solutions that meet specific customer needs. Recent research published by Transparency Market Research indicates that personalized product offerings can increase consumer engagement by up to 30%. By collaborating closely with manufacturers, companies can explore custom formulations, colors, and textures of EVA foam, expanding their product lines and enhancing brand differentiation. This strategic partnership not only fosters innovation but also optimizes production efficiencies and reduces time-to-market, crucial factors in today’s fast-paced business environment.